Precision Econowind Products

Custom Freestanding Coils

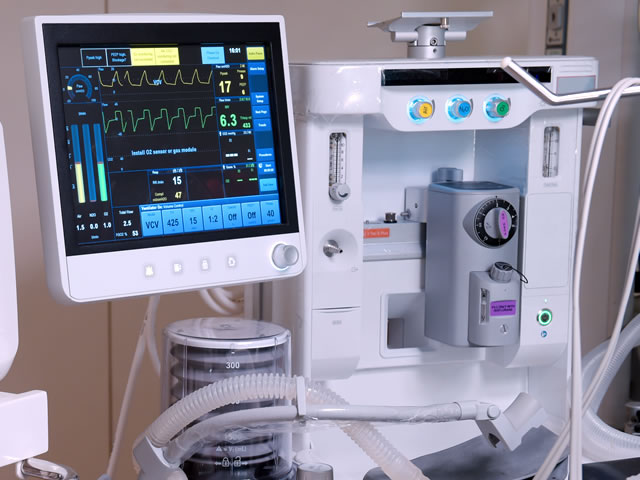

A privately owned American company that manufactures custom coils for the loudspeaker, medical, aerospace, and many other industries.

Custom Freestanding Coils

Our freestanding, self-supporting electric coil manufacturing capability at Precision Econowind offers effective solutions when space is at a premium.

Custom designs can be wound in a round, rectangular, D-shape, or a variety of other custom coil shapes. Eliminating the bobbin saves precious space in size constrained environments. Coils can be wound from round or flattened copper, aluminum, or copper clad aluminum wire. Precision layering techniques further save space and provide the highest quality coil performance. Inner diameters can be held to tolerances as tight as ±0.001”.

- General Capabilities

- Custom Designs (Customer provided)

Contract

Production

Small Parts

Precision Layered

- Coil Shape

- Round

Rectangular

D-Shaped

Flat Wire

Edge Wound

Flat Wound

Other Custom Shapes

- Coil Winding Process

- Free Standing

Single Layer

Multi-Layer

Wet Wound

Flat Wire (Edge Wound or Flat Wound)

Bifilar Windings

Multifilar Windings

Dual Coils

Quad Coils

- Wire Material

- Copper

Aluminum

Copper Clad Aluminum (CCA)

- Wire Shape

- Round

Rectangular

Flat

- Insulation Material

- Low Temp (155°C)

High Temp (220°C)

- Max Adhesive Temperature Rating

- > 220°C

- Wire Size (AWG)

- #16 to #48 AWG

- Coil Winding Minimum Inner Diameter (ID)

- 0.062” – 10.0”

Other sizes available with custom tooling

- Winding Inner Diameter (ID )Tolerance (+/-)

- ±0.001” smaller coils

±0.003” larger coils

- Added Value Processes for Coil Finishing

- Stripping

Tinning

End Connector Assembly

Electrical Testing

- Coil Winding Equipment

- Manual Coil Winding Machines

CNC Coil Winding Machines

Soldering Irons/Posts

Soldering Equipment

Automated Stripping

Automated Tinning

- Testing Equipment

- Ohm Meters

Inductance Meters

Turns Counting Equipment

- Testing Capabilities

- Resistance

Turns Count

Inductance

- Secondary Services

- Assembly

Blanket Orders

Carrying Stock for Customers

- Production Volume

- Prototype

Small Run

Large Run

- Typical Lead Time

- 3 Weeks Typical

Additional Time Required for Tooling

Rush Services Available

Our proprietary high temperature adhesive ensures that the coil maintains its structure at operating temperatures reaching over 500°F. A range of sizes from 0.062” to 10.0” inner diameter coils can be produced with wire from #16 AWG to #48 AWG. Stripping, tinning, and end connector assembly services as well as electrical testing are also available.

We accept blanket orders to help customers further lower costs and carry stock on customer items as an added service. The typical lead time on a custom order is 3 weeks, but every effort is made to accommodate rush orders. If custom tooling is required for nonstandard shapes or sizes, additional time may be required. For more information about our self-supporting electric coil winding capability, see the table below, or contact us directly.

- Industry Focus

- Loudspeaker

Medical

Aerospace

Consumer Products

Industrial Components

- Intended Applications

- Solenoids

Voice Coil Motors

Space Constraint Applications

- Industry Standards

- ISO 9001:2015

ISO 14001

ISO 13485:2003

- File Formats

- PDF

Custom Sketches

Verbal Descriptions